Difference between revisions of "Chemical Vapor Deposition"

Cmditradmin (talk | contribs) m (→Significance) |

Cmditradmin (talk | contribs) m |

||

| Line 1: | Line 1: | ||

<table id="toc" style="width: 100%"> | <table id="toc" style="width: 100%"> | ||

<tr> | <tr> | ||

<td style="text-align: center; width: 33%">[[Main_Page# | <td style="text-align: center; width: 33%">[[Main_Page#Synthesis_and_Fabrication|Return to Research Tool Menu]]</td> | ||

</table> | |||

</tr> | |||

</table> | |||

=== Background === | === Background === | ||

Revision as of 09:43, 11 October 2011

| Return to Research Tool Menu |

Background

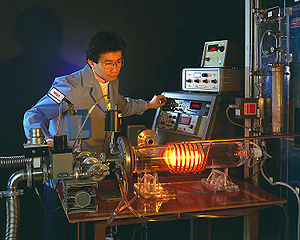

Chemical Vapor Deposition is a common technique for apply thin films to electronic devices. Chemical reagents are supplied as gases into chamber and allowed to react or decompose at the surface of as substrate and form a new substance.

Significance

Batch CVD CVD is a high volume, high purity process that can be conducted with low vacuum. In this technique the sample is loaded into a sample holder that can be heated. The bell jar is evacuated and deposition of the sample occurs. Thickness of the coating can be precisely controlled by timing.

<swf width="400" height="400">images/b/b0/Cvd_bell.swf</swf>

Continuous Flow CVD In this method heated reactants are fed into the chamber continuously. The reaction happens close to the moment of deposition. The flow rate of the gases can be used to efficiently support the stoichiometry of the reaction.

<swf width="600" height="400">images/6/62/Cvd.swf</swf>