Difference between revisions of "OFET fabrication and characterization"

Jump to navigation

Jump to search

Cmditradmin (talk | contribs) m (→Significance) |

Cmditradmin (talk | contribs) m |

||

| Line 4: | Line 4: | ||

===Significance=== | ===Significance=== | ||

All parts of an OFET can be made from plastics or thin flexible metals so that this could be used for flexible or printed electronics. | All parts of an OFET can be made from plastics or thin flexible metals so that this could be used for flexible or printed electronics. | ||

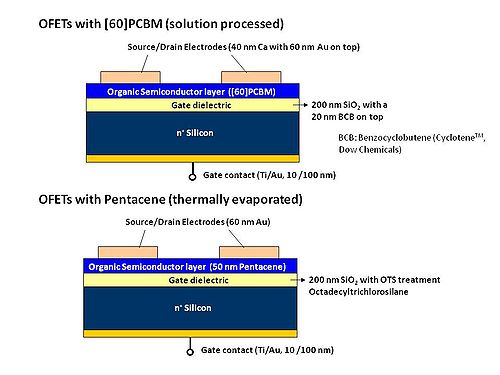

[[Image:OFET-2Device_structures.jpg|thumb|500px|Solution processed and thermally evaporated OFET Device structures | [[Image:OFET-2Device_structures.jpg|thumb|left|500px|Solution processed and thermally evaporated OFET Device structures]] | ||

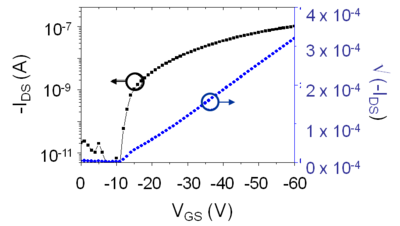

[[Image:Transfer_curve.png|thumb|400px|right| The OFET transfer curve showing source drain current in black and the squareroot of the source drain current in blue, plotted against the gate voltage. ]] | |||

<br clear='all'> | |||

===Operation=== | ===Operation=== | ||

===Links=== | ===Links=== | ||

see [[Organic_Field_Effect_Transistors]] | |||

Revision as of 10:29, 18 April 2011

Background

The organic field effect transistor has a layered construction. A voltage applied to the gate causes the polymer layer to become a semiconductor and allows current flow between the source and drain contact.

Significance

All parts of an OFET can be made from plastics or thin flexible metals so that this could be used for flexible or printed electronics.