Difference between revisions of "OFET fabrication and characterization"

Jump to navigation

Jump to search

Cmditradmin (talk | contribs) m |

Cmditradmin (talk | contribs) m (→Significance) |

||

| Line 3: | Line 3: | ||

===Significance=== | ===Significance=== | ||

<swf width=500 height=400>images/0/04/Ofet_roll_short.swf</swf> | |||

All parts of an OFET can be made from plastics or thin flexible metals so that this could be used for flexible or printed electronics. | All parts of an OFET can be made from plastics or thin flexible metals so that this could be used for flexible or printed electronics. | ||

| Line 9: | Line 11: | ||

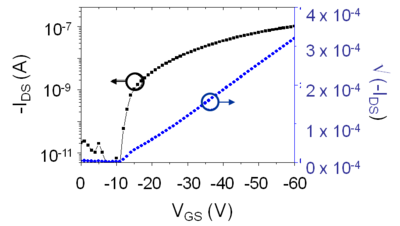

[[Image:Transfer_curve.png|thumb|400px|right| The OFET transfer curve showing source drain current in black and the squareroot of the source drain current in blue, plotted against the gate voltage. ]] | [[Image:Transfer_curve.png|thumb|400px|right| The OFET transfer curve showing source drain current in black and the squareroot of the source drain current in blue, plotted against the gate voltage. ]] | ||

<br clear='all'> | <br clear='all'> | ||

===Operation=== | ===Operation=== | ||

Revision as of 13:13, 22 June 2011

Background

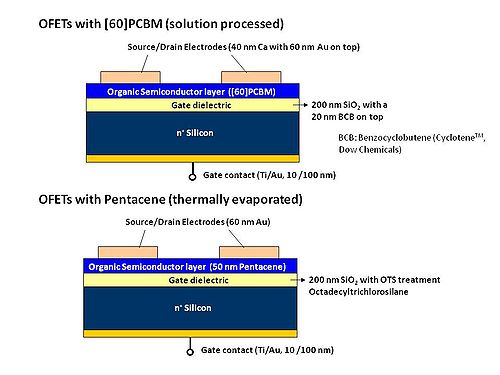

The organic field effect transistor has a layered construction. A voltage applied to the gate causes the polymer layer to become a semiconductor and allows current flow between the source and drain contact.

Significance

<swf width=500 height=400>images/0/04/Ofet_roll_short.swf</swf>

All parts of an OFET can be made from plastics or thin flexible metals so that this could be used for flexible or printed electronics.